290T Oxford Cloth with Recycled RPET: Waterproof, Eco-Friendly Fabric for Outdoor Luggage & Gear

When the Outdoors Meets Responsibility: A Quiet Revolution in Materials

Imagine standing atop a windswept ridge, rain slicing through the air, your backpack the only barrier between you and the storm. You trust it not just to carry your gear, but to endure—without costing the earth more than it should. Today’s outdoor enthusiasts demand more than durability; they seek integrity. They want gear that performs under pressure and respects the planet it explores. Yet, traditional nylon and polyester fabrics, while tough, come at an environmental cost—derived from fossil fuels, slow to degrade, and often ending up in landfills or oceans. The tide is turning. A new generation of materials is rising, one that answers both the call of adventure and the whisper of responsibility.

From Plastic Bottles to Backpack Shells: The Journey of 290T Oxford Cloth

Beneath the rugged surface of today’s most trusted outdoor gear lies a quiet miracle: fabric born not from oil, but from what we once threw away. RPET—recycled polyethylene terephthalate—starts life as used plastic bottles collected from recycling streams. These bottles are cleaned, crushed into flakes, and purified before being melted and extruded into fine, resilient fibers. This transformation—from landfill-bound container to load-bearing textile—is nothing short of alchemy. Woven into a tight 290-thread-count Oxford structure, this fabric emerges stronger, lighter, and far kinder to the environment. Every square meter tells a story of renewal, proving that sustainability doesn’t mean sacrifice.

What Does 290T Really Mean? Strength Woven Into Every Thread

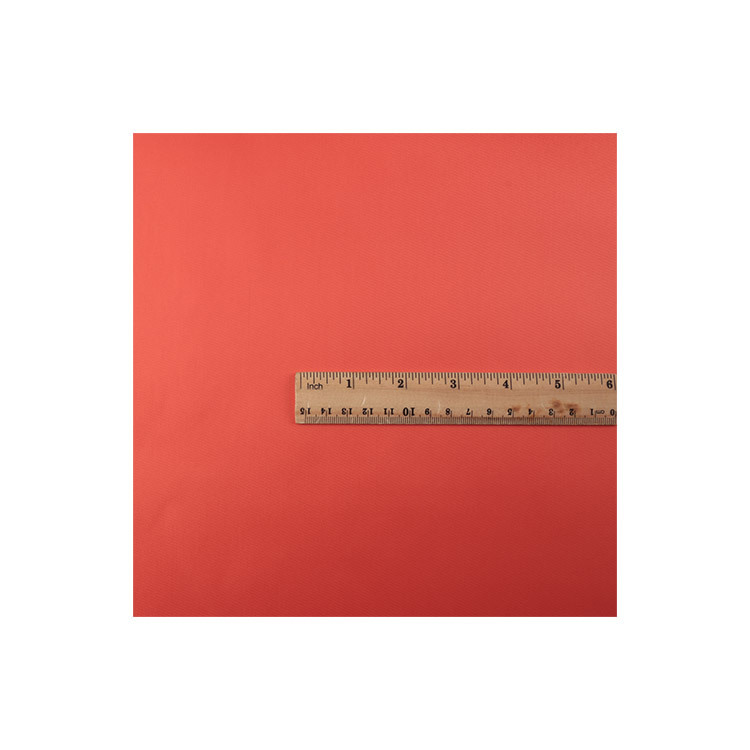

The “290T” in Oxford cloth isn't just a number—it's a promise of resilience. The "T" stands for thread count per square inch, a direct indicator of fabric density. At 290 threads, this material strikes an ideal balance: dense enough to resist tears and abrasion, yet flexible enough for ergonomic design. In real-world testing, bags made with 290T outperform lower-thread-count alternatives when dragged over rocky trails, stuffed to capacity, or subjected to repeated zippering under load. It resists fraying at stress points and maintains structural integrity even after months of use. This isn’t just strong fabric—it’s smart engineering disguised as cloth.

Rain, Mud, and Mist: How This Fabric Keeps You Dry

Weather waits for no hiker, but neither does this fabric. The 290T Oxford cloth features a durable PU (polyurethane) coating applied to its underside, creating a hydrophobic barrier that repels water without sacrificing breathability. Under a simulated downpour, droplets bead and roll off like mercury on glass. In humid campsites or fog-drenched forests, the tightly interlaced weave prevents moisture wicking, keeping contents dry for days. Unlike cheaper laminates that crack or delaminate, this coating bonds securely, enduring folding, stretching, and UV exposure. Whether you're crossing rivers or caught in an alpine squall, your gear stays protected—not by luck, but by science.

More Than Green Marketing: How Sustainability Rewrites Brand Stories

Leading outdoor brands aren’t just adopting RPET—they’re building their identity around it. Companies like Patagonia, Deuter, and Osprey have integrated recycled fabrics into core product lines, resonating deeply with eco-conscious consumers. Studies show that over 65% of millennials prefer brands that demonstrate environmental accountability. When customers see “made with recycled plastic bottles” on a tag, it sparks trust. It turns a functional purchase into a values-driven choice. And when that product lasts longer and performs better? Loyalty follows. The narrative shifts from consumption to contribution—one backpack at a time.

Can Performance and Planet Coexist? The Truth Behind the Test Data

Skeptics once asked if recycled meant reduced performance. Real-world data says otherwise. Independent tests reveal that RPET-based 290T Oxford matches virgin polyester in tensile strength and exceeds it in UV resistance due to enhanced stabilizers. After 500 hours of accelerated weathering, color retention and fiber integrity remain superior. While challenges remain—like improving dye uptake efficiency and expanding post-consumer recycling infrastructure—the trajectory is clear. With innovations in closed-loop production and low-impact dyes, the future of outdoor textiles isn’t just sustainable—it’s regenerative.

Why Designers Are Falling in Love With This Material

For product designers, 290T RPET Oxford is a dream canvas. It cuts cleanly, sews smoothly, and holds stitching with remarkable tenacity—critical for high-stress seams on heavy-duty packs. Its moderate weight supports lightweight construction without compromising protection. Available in a spectrum of colors, it accepts dyes evenly, allowing bold branding or subtle earth tones alike. One designer shared, “It gives us the freedom to innovate—lighter frames, smarter compartments—knowing the fabric won’t let us down.” More than a material, it’s a design partner aligned with both aesthetics and ethics.

Your Next Adventure Starts With a Choice

The next time you shoulder your pack, pause. That fabric against your back? It might have once held someone’s drink on a summer day. Now, it carries your shelter, food, and dreams across mountains and cities alike. In every thread of 290T RPET Oxford cloth flows a story of transformation—of waste reborn, of nature protected, of journeys powered by purpose. The outdoors has always called us to explore. Now, it asks us to care. What story will your gear tell?